Ruckus is a Make or Break Moment for the Handcrafted Movement

The first time Polina Osherov saw the place, she snuck in for a photo shoot. It was 23,000 square feet of open space in a metal warehouse just north of 10th Street on the near-east side. No walls or dividers segmented the enormous interior, save for a grid of poles. In the vaulted ceiling, lighting and wiring were exposed. Dents marred the filthy surface of the floor. Osherov, co-founder of the local fashion group Pattern—which puts out Pattern magazine and operates the Pattern Workshop on Mass Ave, among other things—thought the building’s gritty, rundown, industrial look made the perfect backdrop for a fashion spread. Who would mind a quick photo shoot? After all, the space looked unusable for any other purpose.

So imagine her surprise when, years later, one of her collaborators suggested the same property as the potential location for Ruckus, an idea Osherov had for a hub where people who make things could share concepts and equipment. Sure, the maker movement was gaining momentum. Stores such as Homespun were bursting at the seams with locally made items, and Indy restaurants were beginning to buy locally made furniture and interior design elements. But that warehouse Osherov remembered from her fashion shoot? It was a disaster.

Like all good craftspeople, however, the project leaders decided to look beyond the raw material in front of them and envision what was possible. Osherov saw a space that could support the growing fashion community she had helped to build and generate new businesses for the city. Michael Bricker, co-founder of People for Urban Progress, saw the potential to encourage a new generation of metal- and woodworkers to follow in his company’s footsteps. Leaders at Riley Area Development Corporation, a community group supporting the project, saw a chance to revitalize the somewhat rough area and turn an underutilized building into a space that could offer job opportunities. Larry Jones, president of Teagan Development (which eventually purchased the building) saw a business opportunity. The Cottage Home area was up and coming, and this might be the sort of project that would make the neighborhood the next overnight sensation.

This spring, Ruckus will open, revealing an impressive remodel. Where there were holes in the floor, there’s now a bike lane running through the halls. (Hello, millenials!) Where there was exposed wiring, there’s now contemporary lighting. But exactly who will sign up to fill the space remains as nebulous as Indy’s maker community itself. We’re about to find out how robust that group really is.

In the early 20th Century, Indy had a strong entrepreneurial base, particularly in the automotive sector. Marmon Motor Car Company made the first car with a rearview mirror. Local legend Carl Fisher had the bright idea of headlights. And when a tinkerer named Louis Schwitzer decided to make cooling pumps and superchargers for vehicles in the 1920s, he built a huge manufacturing warehouse on the near-east side—the space where Ruckus will be.

After World War II, however, the maker culture languished here. As technology advanced, machines began to replace manual labor, and many new industries emerged that didn’t require working with your hands. For the next 50 years, very few Hoosiers would classify themselves as professional makers of anything.

Then, in the early 2000s, something changed. Nationwide, young people started to embrace the skills of their grandparents. Some say the movement was a response to international outsourcing of previously American-made goods. Others argue it stemmed from millennials’ desire to create their own work schedules and find fulfillment in their jobs. Whatever the case, makerspaces equipped with woodworking tools, 3-D printers, blowtorches, and other machinery started popping up in places such as San Francisco and Boston.

There aren’t any official statistics on how many makers are located in Indianapolis, but Osherov says she has been hearing for years that a new work space would solve problems for the fashion community here. For instance, after a fashion designer has made sketches and created a design, he or she needs to produce the garment commercially. In other cities (usually larger ones), cut-and-sew facilities fill that role. Here, designers must hire their own temporary employees, the availability of which can be unpredictable. With so many designers facing the same problem, Osherov wondered if pooling resources to rent a space might be the solution. She decided to start small.

In August of 2013, Pattern organized The Bindery, a free, month-long co-working pop-up space for the creative community. They took over one of the galleries in the Harrison Center for the Arts and filled it with sewing machines, dress forms, and tables, and hosted workshops to encourage innovation and collaboration. More than 300 creatives mobbed the place. Encouraged by the turnout, Osherov nevertheless realized that scaling up would require a lot of money. She started talking with Bricker of People for Urban Progress about how they might fund a more permanent project. With the concept seemingly proven, they waited for the right timing.

Finally, last winter, Indianapolis announced a $1.5 million grant for projects that would address issues like urban blight, job creation, rehabilitating structures, and expanding business opportunities. The Community Development Block Grant would be the largest single grant available from the city. Local leaders encouraged Osherov and Bricker to submit their makerspace idea, and Riley Area Development Corporation (RADC) helped them navigate the paperwork. After weeks of research, bureaucratic complications, and hard work, RADC won the grant and the team began to dream.

Dubbing the place Ruckus—which evoked creativity, and the feeling of things being loud and messy—Osherov and company created social-media accounts and a website. In an effort to include as many people in the community as possible, they posted a survey on the Ruckus website to gather opinions, and received more than 100 submissions. Osherov also launched a co-working space called the Pattern Workshop on Mass Ave where four makers shared a small studio—a sort of microcosm of what they hoped Ruckus would be. The makers there provided feedback about the potential new space.

The first of those, Rachel Ramey, started Rachel Ramey Design to create clothing for young women sick of Forever 21. From what she hears, there are many fashion designers in Indy who plan to become members of Ruckus, and she thinks it will be a great place to collaborate and share expensive, professional textile machinery. But the idea won’t necessarily work for everyone. Another Workshop alum, Christian Resiak, started Howl & Hide, a handmade leather-goods company, about a year ago. He doubts he will become a Ruckus member. After all, his leather goods are handmade, so he wouldn’t benefit from shared machinery. Chelsea van der Meer and Eric Stine run Yonder Bound, a bindery operation that creates logbooks. They, too, are unsure if the space will be suited to their trade, which requires specific binding machines that wouldn’t be useful to many small businesses.

Still, the feedback was mostly encouraging. Many of these makers, even the ones who might not benefit directly from the space, think Ruckus will help Indy’s craftspeople to network. But no one really knows how many of those makers there are, or what they collectively want. That will likely remain a mystery until the place opens its doors.

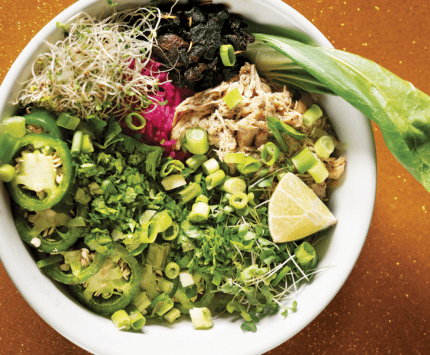

When Ruckus launches a few months from now, potential members will find the space divided into three sections: textiles, metalwork, and woodworking. It also hosts a photography studio, a gallery, conference rooms, and event space. Membership options will include “Tinkerer,” the lowest level at $85 per month; “Tailor,” for someone who wants to use the textile equipment and laser cutters at $135; “Soldier,” for a heavy-duty-equipment user at $135; and “Spy,” for the person who wants it all at $165.

Osherov and her partners hope to recruit individuals who have decided to make making a fulltime gig: furniture craftspeople who require more space, fashion designers who need professional machines to meet production demands, metalworkers who want access to industrial tools they could never afford on their own, and entrepreneurs who prefer working in groups.

At the same time, they also want to ensure the space integrates into the community. The interior bike trail is intended to promote Ruckus as a place to visit, a spot to show off to the public. And the founders plan to host maker fairs and workshops. But they aren’t sure exactly how business-minded entrepreneurs will mix with hobbyists. What about the retired person who is considering a second career in fashion, or the weekend warrior who makes furniture on the side? How will the entrepreneurs feel about the amateurs taking up space on machines?

The makers who end up becoming members will determine which machines and resources are provided. Certain machines are already in the lineup to purchase (or have been gifted to Ruckus) due to the feedback from website submissions. And based on the three discipline-specific areas, organizers have a sense of the basic machines they will need, with the idea that the rest will develop organically with demand.

Which leads to the big question, the question that always plagues non-profits: How will they pay for it all? The $1.5 million grant was used to construct and furnish the space. Now, Ruckus needs staff for workshops, safety classes, and marketing, along with money for rent. All of that cash will have to come from memberships, fundraising, and grants. From her work with Pattern, Osherov knows first-hand that funding non-profits can be incredibly difficult. This is the part she worries about most.

Of course, none of that will be a problem if several hundred makers arrive on day one to sign up for memberships. Maybe thousands of them are currently toiling away in Indy garages and basements, pining for a place to collaborate and construct. When you’re trying to build something as big as Osherov and company are, drill presses and sewing machines will only take you so far. You also need a little luck.