Why Mask-Makers Will Never Get To Stop

Handmade with love and appreciation Photo courtesy Community Health Network

Nine weeks ago—for reference, those were the innocent days when canceling March Madness still felt apocalyptic and surreal—an Evansville hospital issued a public plea for homemade cotton face masks. Rachel Maddow reported it. Literally overnight, the nation’s sewing-machine owners sprang into action. It felt like the scene in Three Amigos when the villagers make mariachi costumes for everyone. I was one of thousands dusting off a Brother or a Singer. Masks are easy to make—a simple rectangle—so we, the amateur sewers of the nation, thought we could do this. But I didn’t think that we’d still be doing it deep into spring. It was supposed to be a distraction, a quaint wartime Rosie the Riveter response, more for us than them. Right? I mean, the modern American hospital can 3-D-print body parts, while I spend two hours wrestling with my thread tension. They surely wouldn’t rely on hobbyists to keep them in life-saving garments for long.

Yet here we are, 90,000 deaths later, and the mask-maker corps is still going strong, still triaging requests for masks, donated fabric, and emails about who has elastic. The best metaphor I heard early on, from a national mask-making group that was looking for boots on the ground in Indiana, was that collectively everyone was “building an airplane in the sky.” The grassroots effort took off without precise coordinates—which mask pattern hospitals would accept, which fabric was the most effective to use, and so on.

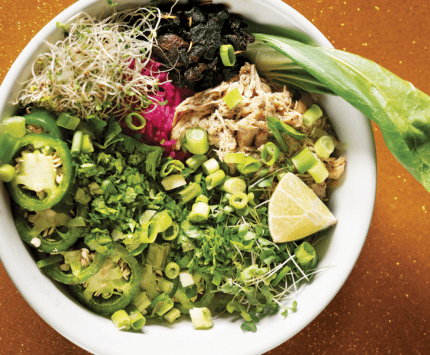

Somehow, it worked. Within a couple weeks, hospitals issued guidelines and collection protocols. Rainbows of face masks became the new online food porn for a while— “finished 125 today!” Word spread as fast as the virus itself. Once, a woman I didn’t know emailed me to donate $200 worth of material. I put on a mask to go pick it up from Crimson Tate fabric store on Mass Ave. It was sitting on the sidewalk in a Lululemon bag. I divvied it up among volunteers around town, women I had connected with on Facebook who now dominate my text threads. Then a nonprofit in child-protective services sent an errand-runner to a sewer’s house to pick up the masks. They were used by adult staffers in the field. I couldn’t guarantee a turnaround time—we’re all volunteers.

After a month or so, we reached cruising altitude. All of the early turbulence—questions about the best pattern and anecdotal input from anyone who knew a nurse—smoothed out. About any style of mask would work, quilting fabric was a good choice, and old T-shirts would work, too. A pocket for a filter wasn’t essential. Elastic digs into the ears over the course of a long shift, but it’s better than nothing. Male healthcare workers are fine wearing a feminine fabric—they have more important concerns. Homemade masks would be used by healthcare workers who aren’t directly treating COVID-19 patients, as well as hospital visitors. Meanwhile, more coordinated responses from governments and hospitals took shape. The Indiana Economic Development Corporation made deals with some manufacturers to switch production to masks and gowns, spending upwards of $5.5 million. For example, one furniture-maker in Northern Indiana trained its in-house sewers to make 3,000 gowns a day. Community Health Network employees who owned a 3-D printer started making a doo-dad called an EarSaver to keep the elastic loops from digging into the skin.

EarSaverCourtesy Community Health Network

But just when I thought our Rosie the Riveting might be winding down as the industrial machine revved up, I talked to Community Health about their needs and response. In addition to the EarSaver, a nose barrier is on the drawing board, too. In fact, CHN was developing a Covid Comfort collection, for now available only to its staff. Wendy Horn, Community’s vice president of business development, implied that it could become a product line they sell down the road. That’s when I realized the cottage mask industry was much bigger than I had thought.

Indeed, masks are already a commodity, going for about $12 online. Billie Eilish wore a Gucci mask, and the form became high art when a Belgian design studio turned old Nike sneakers into lace-up face coverings. This is what I was afraid of when we started building the airplane—that people would forget we were on a mission, not a joyride. It bothered me for a while that hobbyist sewers—the crucial labor—were making masks for their neighbors and friends while workers closer to the front lines still needed them by the thousands. It’s easy to make a no-sew mask with a T-shirt, and it seemed like people sheltering in place could get by with one of those while all available sewers concentrated on the more urgent needs. Sure, any mask made was helpful. But I thought we could aim higher than “better than nothing.” Politics crept in, too—some sewers in our group were professionals and needed to be paid, while others were almost offended by the suggestion. Intentions were good, but eventually every fabric threatens to unravel.

On the plus side, there was so much good to observe. Crimson Tate, for instance, in addition to donating fabric and elastic early on, figured out a great system for taking orders for masks and farming them out to their customers to sew, offering $1 per mask in the form of a store credit. My friend who has made more than 1,000 masks came up with one for those who talk to lip readers–it has a clear plastic panel over the mouth. Then, just when we needed a laugh, there was a woman in Utah who used this NSFW fabric and told people, “If your can see what it is, you’re too close.”

Too many sewers to count have made too many masks to count, often on their own dime. And it made them happy. Ultimately, I decided I wasn’t in a place to judge anyone else’s approach, and truthfully, an extra 100,000 masks here or there probably would have been just a drop in the bucket. I thought things were quieting down recently, then someone emailed and said the United Way and the Red Cross need kids’ masks—small sizes are hard to come by. Also, some fabrics scare toddlers and infants—does anyone have cartoon fabric? When medical specialists’ offices start reopening, the need for masks will increase. When all businesses start reopening, the need will increase. When schools resume … when air travel returns … when enough people just can’t take it anyone and the floodgates of impatience burst open.

Perhaps soon, it won’t matter what kind of airplane we built. We’ll need a rocketship.